Technical Notes: Laser Induced Damage Threshold

Overview

> General description

> Energy density / Fluence

> Power density / Irradiance

> Dependencies of LIDT

> Wavelength

> Pulse duration τ

> Pulse repetition rate

> Laser beam size (diameter or area)

> Pulse shape

> Quick reference formula

General description

With the increase of more and more powerful laser systems, conventional optics have to withstand these increasing powers. To specify this behavior, the LIDT (Laser Induced Damage Threshold) was induced. It defines a critical laser power or peak fluence, which the lens bulk materials or the coatings cannot withstand and therefore the laser radiation causes permanent changes in the optical characteristics, permanently damaging the lens. With the broad variety of lasers and different thresholds for the LIDT, it is often a very confusing and vague topic. Therefore we will provide some overview and explanations in the following pages. The basis for this information is the international ISO 21254.

Another very important point for durability and resilience of lenses is the topic of Cleanliness.

Energy density / Fluence

The most common LIDT declaration is given as the max. energy density -- also called fluence – which the used material can withstand. The fluence is a unit of laser pulse energy per focal spot area and mostly used for pulsed lasers. For an expressive declaration of the LIDT, not only the value itself, but also the measurement conditions should be given. This includes laser pulse duration, pulse repetition rate and the wavelength.

Power density / Irradiance

When considering cw (continuous-wave) lasers, a definition of the LIDT by a pulse energy does not make any sense. Therefore it is declared as an irradiance, which is described by the laser peak power per effective area (units W/cm² or W/mm²). It is also possible to define the damage threshold by a linear power density (units W/cm or W/mm). If this value is given for the laser, a measurement of the beam size is relevant.

Although the power is defined as laser pulse energy per pulse duration, a conversion between a LIDT in fluence to a LIDT in intensity is not automatically valid. The reason lies in the different destruction mechanisms of the coatings from various laser types.

Dependencies of LIDT

Laser induced damage is dependent on very many factors and therefore it is not possible to guarantee the performance under all possible circumstances. The given conversions in this chapter are therefore just estimates. To ensure a stable and permanent high quality performance of the lenses, we recommend a usage below 50% of the LIDT. Close operation to the LIDT could cause long-term damage.

LIDT values depend – beside the pulse energy or peak power - on the laser wavelength λ [nm], pulse repetition rate R [typ. Hz – MHz], pulse duration τ [fs – ms], laser spot diameter dL [μm – cm] / laser spot area A [μm² – cm²] and the pulse shape. Of course, most of these values only affect the fluency LIDT, as they are pulsed laser values. For cw lasers, only wavelength, pulse shape and sport size are important.

In the following explanations of LIDT dependencies, examples will be given and will all assume an LIDT of 1J/cm², measured at 1064nm with a pulse duration of 1ns and a repetition rate of 50Hz.

Wavelength λ

For any change in the laser wavelength, the LIDT value has to be adjusted. The enery of a photon depends on the wavelength like shown in the following formula:

Shorter-wavelength laser light carries photons with higher energy. This relation also reflects the behaviour of LIDT: Half the wavelength results in the half LIDT value. Great care must be taken with shorter wavelengths. These photons carry much more energy and therefore the actual LIDT value can be much lower than estimated! Thus declarations of the LIDT are meaningfully specified in the wavelength region of their use.

Pulse duration τ

The dependency on the pulse duration scales with the square root. For example, a 100 ns pulse has an approx. LIDT √ 100 = 10 times higher LIDT than that for a 1 ns pulse with comparable pulse energy. This can be counter intuitive! This confusion comes from the separation of the time factor in comparison to the area factor. When calculating the fluency of the laser beam, one does divide the laser pulse energy by the beam area. But at no point in this calculation there is a consideration that laser pulses compress the laser pulse energy in their pulse duration. This means, that a pulse with a shorter pulse duration, but the same overall laser pulse energy, has to compress the same amount of energy into a shorter time interval. This leads to higher peak intensities and therefore a much higher probability of damage. But against intuition, this is not included in the „fluency“ but the LIDT value is only given for a specific pulse duration.

In conclusion a shorter laser pulse does decrease the LIDT value as it has higher peak intensities and therefore a higher chance to damage the material. Thus a conversion of the LIDT value is necessary for diff ering pulse lengths, as it is not directly considered.

Please be aware of this conversion being only valid in the range from around 30 ps to many ms pulse duration. Below the mentioned 30 ps, multi-photon absorption starts to occur, introducing new destruction mechanisms and therefore any optic has lower thresholds in this regime.

For pulse durations larger than 0.1 ms the LIDT for the irradiance has to also be taken into consideration!

Pulse repetition rate

Pulsed lasers with a high repetition rate may show very similar behavior to beams of cw lasers. As this is highly dependent on absorption and heat dissipation, there is no solid rule to determine when an optic will be damaged due to thermal effects. If you are unsure about the power level, please contact SILL.

Laser spot size (diameter or area)

The spot size has an enormous impact on the resistance of the lens materials. As an example, assume a 1064nm laser with a pulse energy of 100mJ. When used with 500μm beam diameter through the lens, it would have a fluence of F = 50.93 J/cm² and therefore surely destroy any material with the stated LIDT = 1J/cm² from above. If the beam is expanded to a 5mm beam diameter instead, the fluence would be F = 0.51 J/cm² and the material should not be damaged at all.

Pulse shape

The rule of thumb about the pulse shape is as follows: As peak intensities are considered, there is a difference between a top-hat like shape and a Gaussian beam. Just note that the LIDT value for a Gaussian beam is half the value of a top-hat shaped one.

Quick reference formula

For a quick estimate of the LIDT for your system with a laser pulse duration larger than 30 ps, the following formula can be used, while "spec" indicates the values from the specification:

As an example, a pulsed laser at 532 nm wavelength and 50 ns pulse duration is used. The given LIDT from the lens supplier may again be 1 J/cm², measured at 1064 nm with a pulse duration of 10 ns. As calculated below, the LIDT can be estimated to be nearly 1.12 times higher.

Destruction mechanisms

The main damage mechanisms strongly depend on the laser properties, but are also dependent on the lens and coating materials in respect to geometrical properties, thermal conduction, absorption, defects, homogeneity, and more.

Thermal absorption has to be considered with the use of cw or long pulse (µs) lasers. The damage is based on heating the lens material until melting, irreversible material expansions or modifications to the lens material. This damage mechanism also has to be considered for short-pulse lasers with high repetition rates, when the material is not given enough time to cool down between pulses.

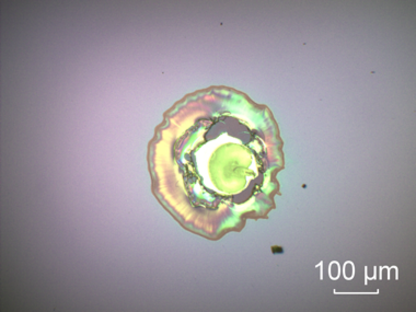

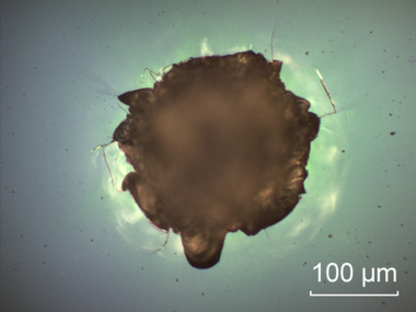

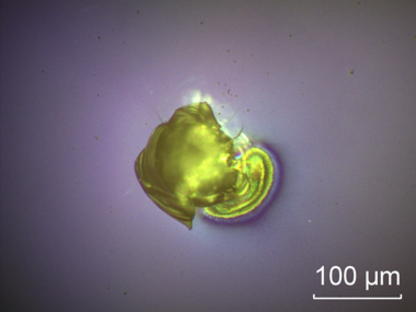

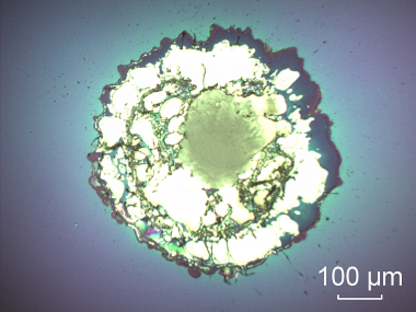

Another cause of damage initially comes to play with short pulse lasers. Local defects or even tiny inclusions can cause plasma build up due to poor thermal conduction. This results in stress based breakthroughs and irreversible changes of the lens optical properties.

Furthermore, when considering ultra-short pulse lasers, additional multiphoton processes can occur ionizing coating materials and producing electrical breakthroughs when reaching critical electron densities.

LIDT of our coatings

In the following table we present the results of measurements of the laser induced damage threshold. They were done in a clean lab environment with acetone cleaned samples. Please be aware that due to coating process variations, geometry of the lens elements and the special testing environment, the real LIDT values might be much lower (rule of thumb is 5-10 times to be sure). Therefore these values are only test results and not a specification. In case of doubt, please contact our experienced team. Otherwise we cannot recompense in the event of damage.